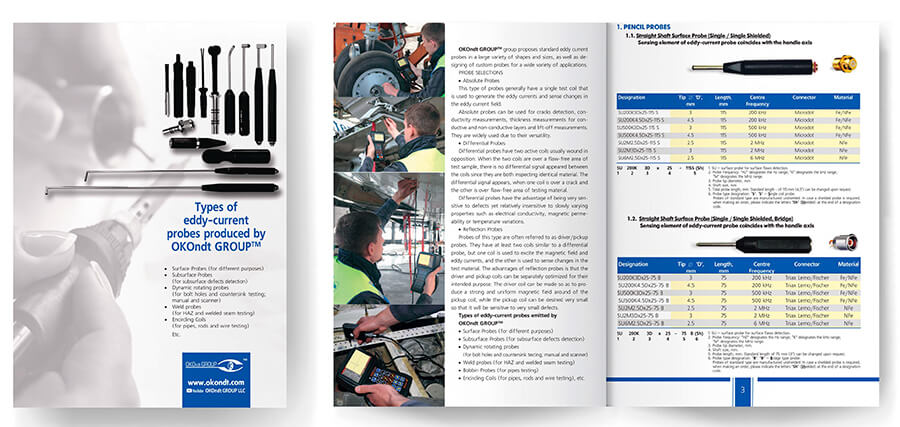

Angle Shaft (L-shaped) Surface ECP:

- typical absolute single-coil probe built according to the “Single coil” scheme

- designed for testing of the complex-shape details with complicated access or parts having protruding elements

- applied together with the eddy current flaw detectors Eddycon C, Eddycon CL and flaw detectors from other producers.

Sensing element of eddy current probe is placed at the angle of 45˚ to the handle axis.

|

Designation |

Tip Ø 'D', mm |

Drop length, mm |

Length, mm |

Centre frequency |

Connector |

Material |

|

SU200K3A4.5Dx6.4-105 S |

4.5 |

6.4 |

105 |

200 kHz |

Microdot

|

Fe/NFe |

|

SU500K3A3Dx6.4-105 S |

3 |

6.4 |

105 |

500 kHz |

Microdot

|

Fe/NFe |

|

SU500K3A4.5Dx6.4-105 S |

4.5 |

6.4 |

105 |

500 kHz |

Fe/NFe |

|

|

SU500K3A4.5Dx12.7-105 S |

4.5 |

12.7 |

105 |

500 kHz |

Fe/NFe |

|

|

SU2М3A2.5Dx2.7-105 S |

2.5 |

2.7 |

105 |

2 MHz |

NFe |

|

|

SU2М3A3Dx2.7-105 S |

3 |

2.7 |

105 |

2 MHz |

NFe |

|

|

SU2М3A3Dx6.4-105 S |

3 |

6.4 |

105 |

2 MHz |

NFe |

|

|

SU2М3A3Dx12.7-105 S |

3 |

12.7 |

105 |

2 MHz |

NFe |

|

|

SU6М3A2.5Dx6.4-105 S |

2.5 |

6.4 |

105 |

6 MHz |

NFe |

|

SU |

200K |

3A |

4.5D |

x |

6.4 |

- |

105 |

S(Sh) |

|

1 |

2 |

3 |

4 |

|

5 |

|

6 |

7 |

1. SU – surface probe for surface flaws detection.

2. Probe frequency:

“HZ” designates the Hz range; “К” designates the kHz range; “М” designates the MHz range.

3. Drop angle of a sensing element to the probe axis “3А” is 45˚.

4. Probe tip diameter, mm.

5. Drop length, mm.

6. Probe length, mm. Standard length of 105 mm (4.1") can be changed upon request.

7. Probe type designation: “S”. “S” – Single coil probe.

Probes of standard type are manufactured unshielded. In case a shielded probe is required, when making an order, please indicate the letters ”Sh” (Shielded) at the end of a designation code.