The UDS2-77 ultrasonic single rail flaw detector is a handpush cart intended for the inspection of one rail line. The product is manufactured in nine modifications and can employ either Slide Search Unit or Roller Search Unit, and contain from 3 to 13 UT probes.

The flaw detector utilizes a unique scanning scheme that allows testing the entire rail section, except for foot flanges, by pulse echo, echo-shadow and echo-image techniques.

-

User-friendly operation

Both mechanics (the cart) and electronics (the software) of the UDS2-77 are ergonomically designed, have a user-friendly intuitive interface, as well as they are resistant to severe weather conditions that may occur during operation on a railroad.

-

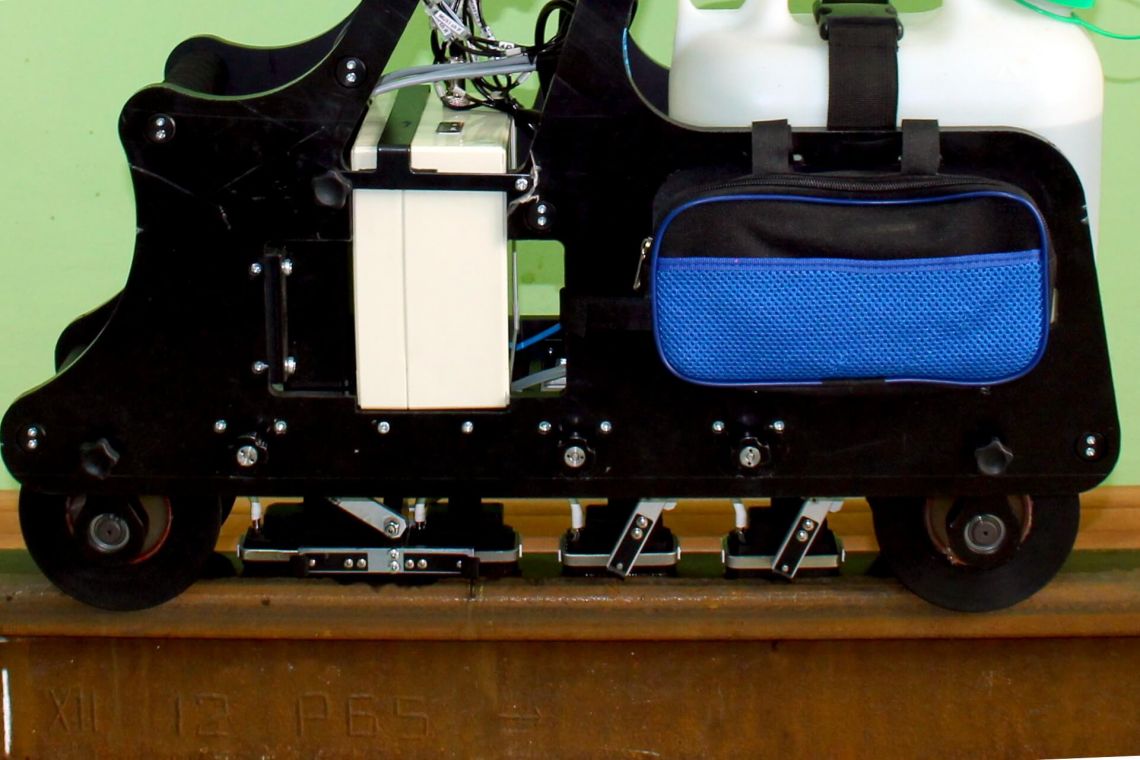

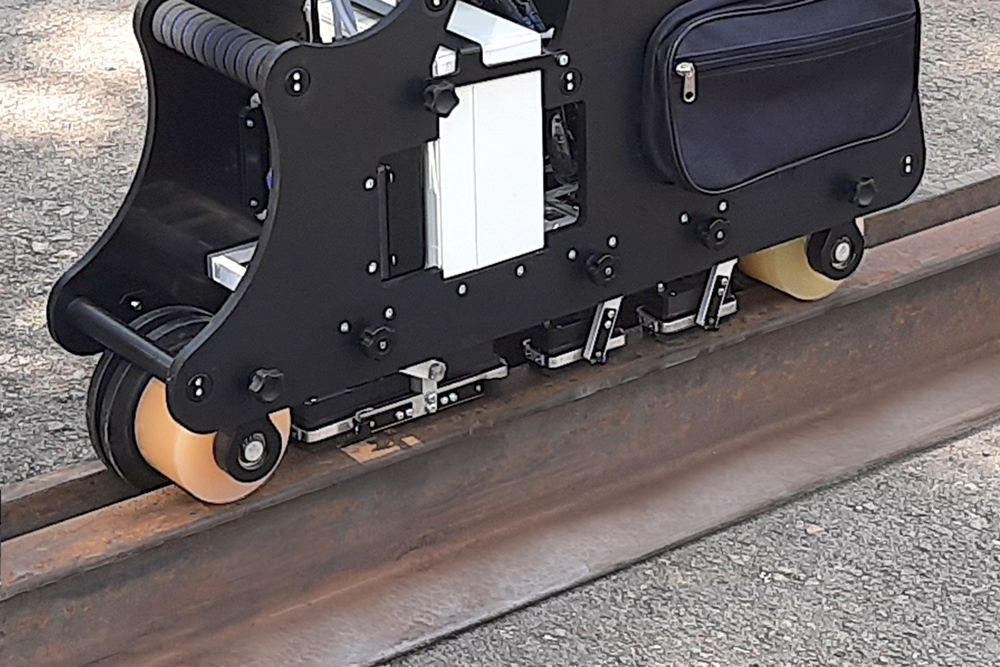

Handcart design

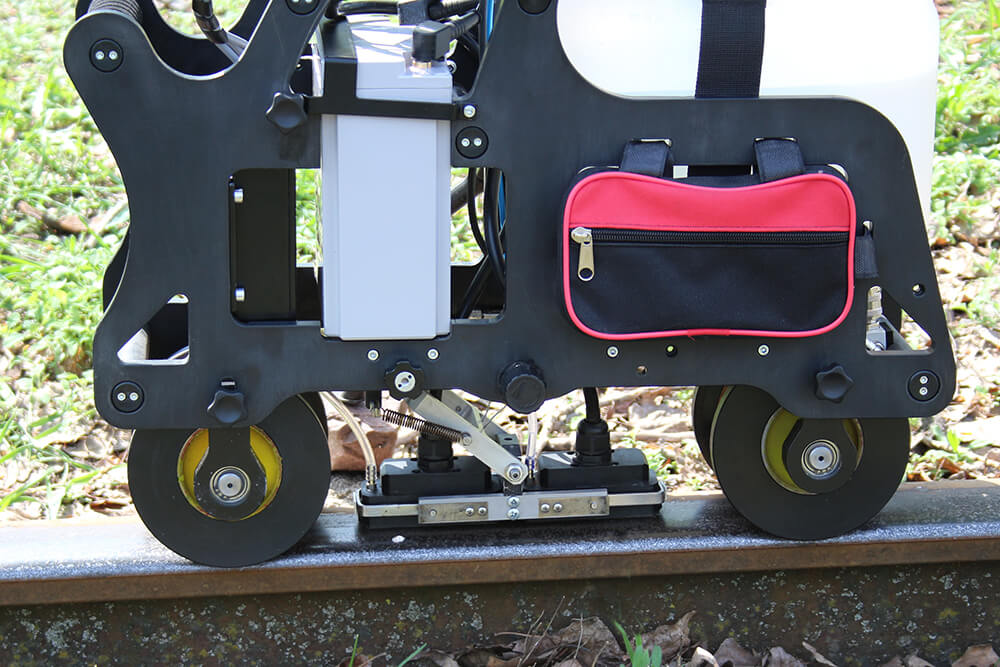

- Weight of the cart is 16 kg only.

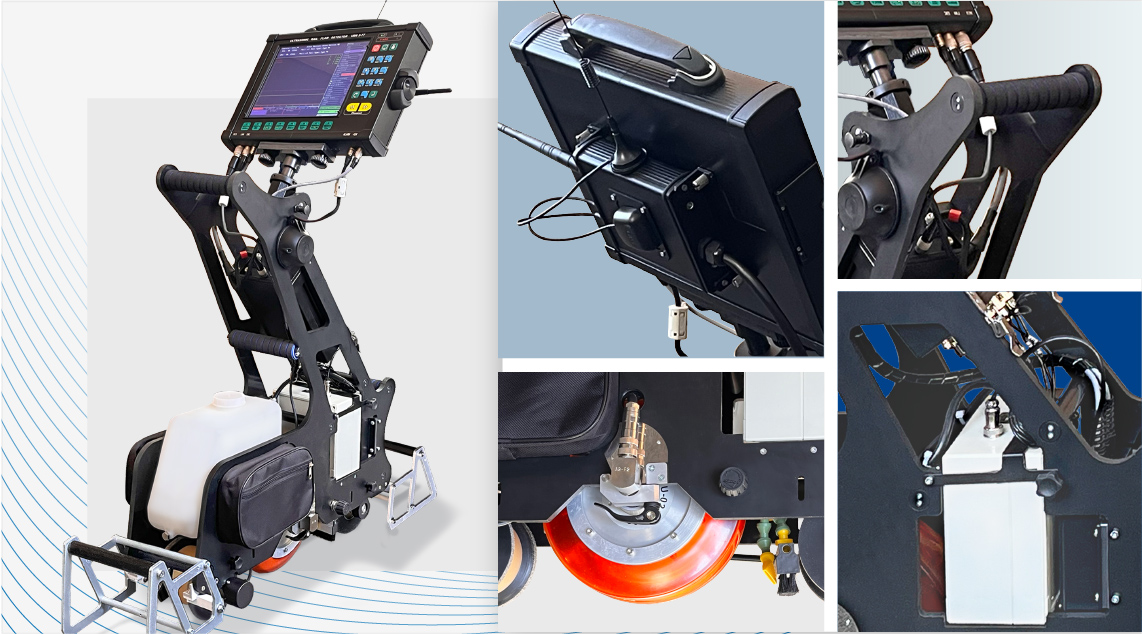

- Modular design of the cart consists of a support frame with adaptive rollers; electronic unit for control and visualization; multichannel unit (MUX); battery pack; couplant (water) tank; probe units; suspension mechanism of the probe units to place them into operation/transportation position; encoder.

- The position of the electronic unit for control and visualization can be adjusted along three axes

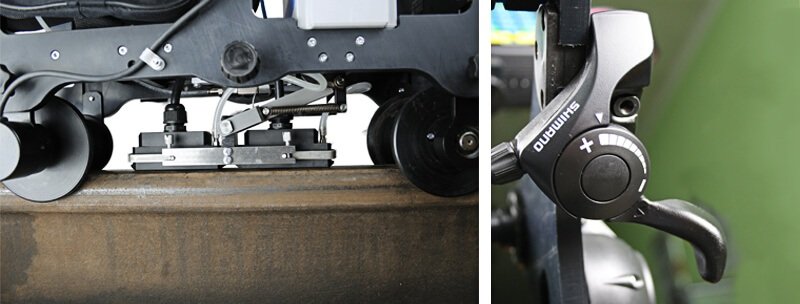

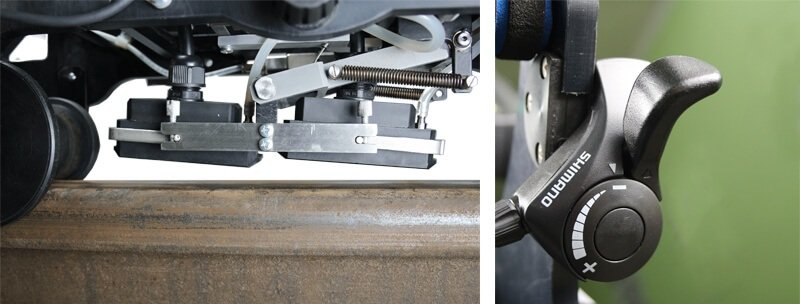

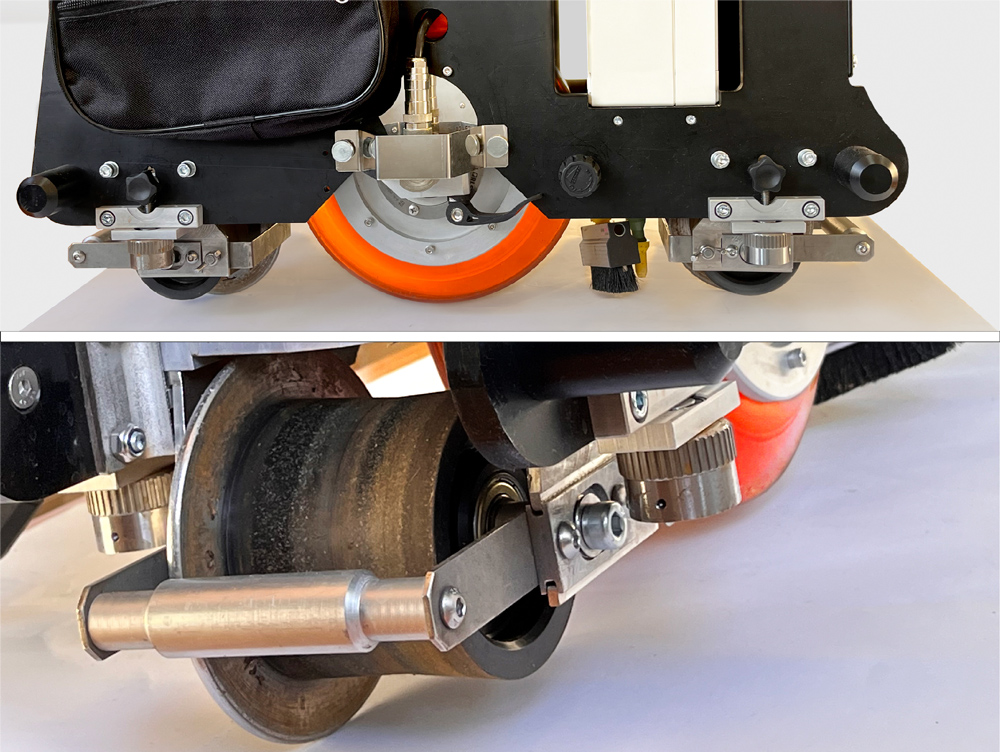

- The probe unit (slide or roller) is positioned cross-wise to the rail with the aid of a dedicated control device

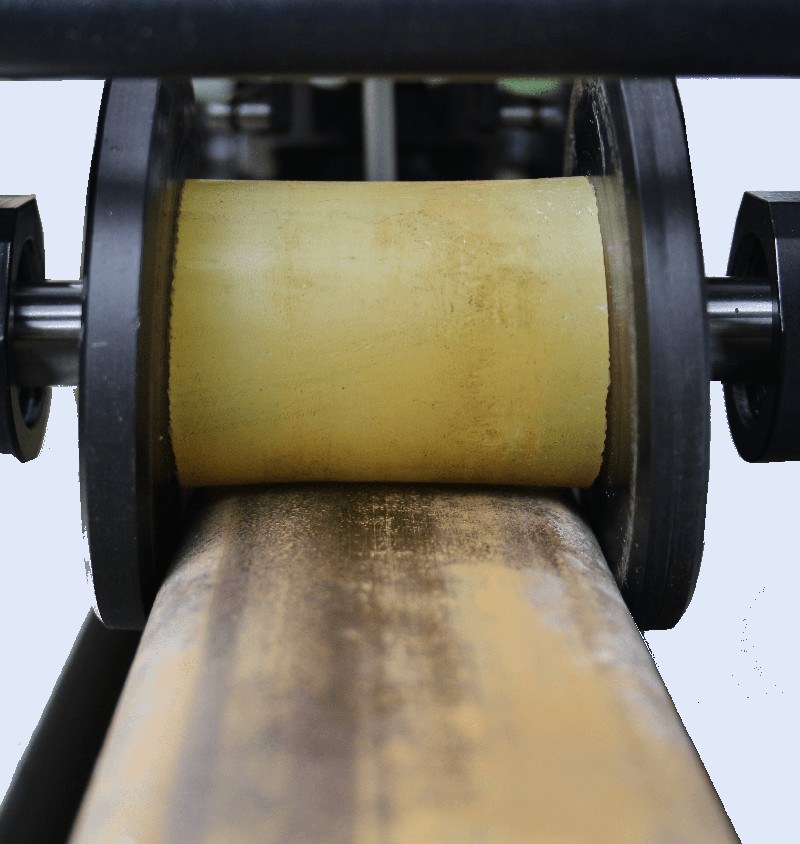

- The probe unit can be centered using the adaptive roller

- The suspension mechanism of the probe unit ensures a stable coupling if the cart is tilted for up to 15°

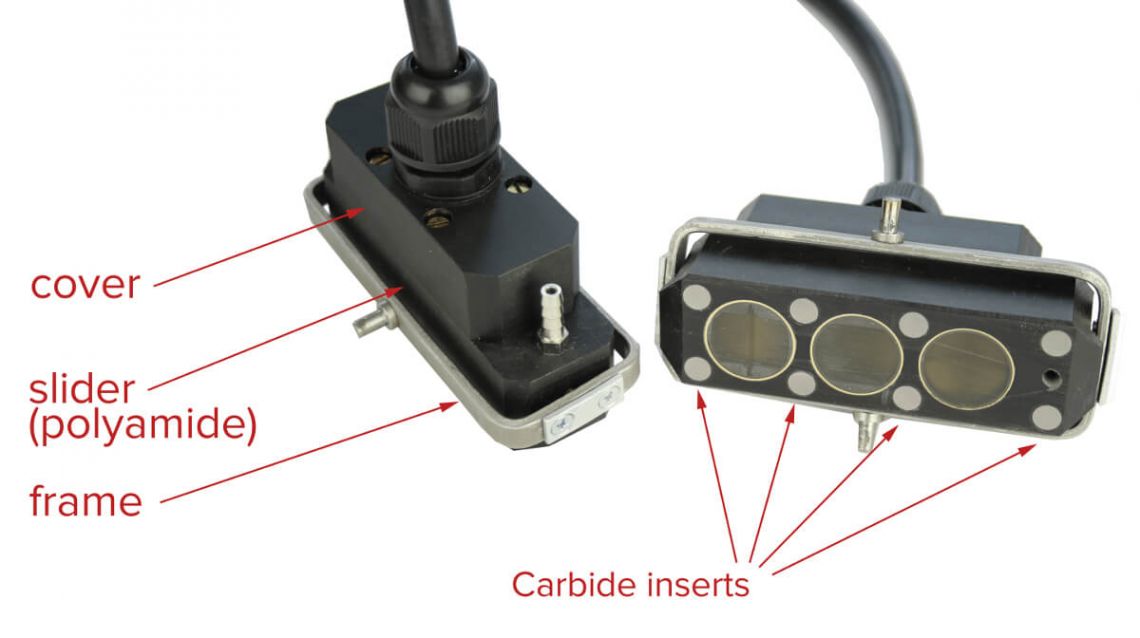

Slide probe unit

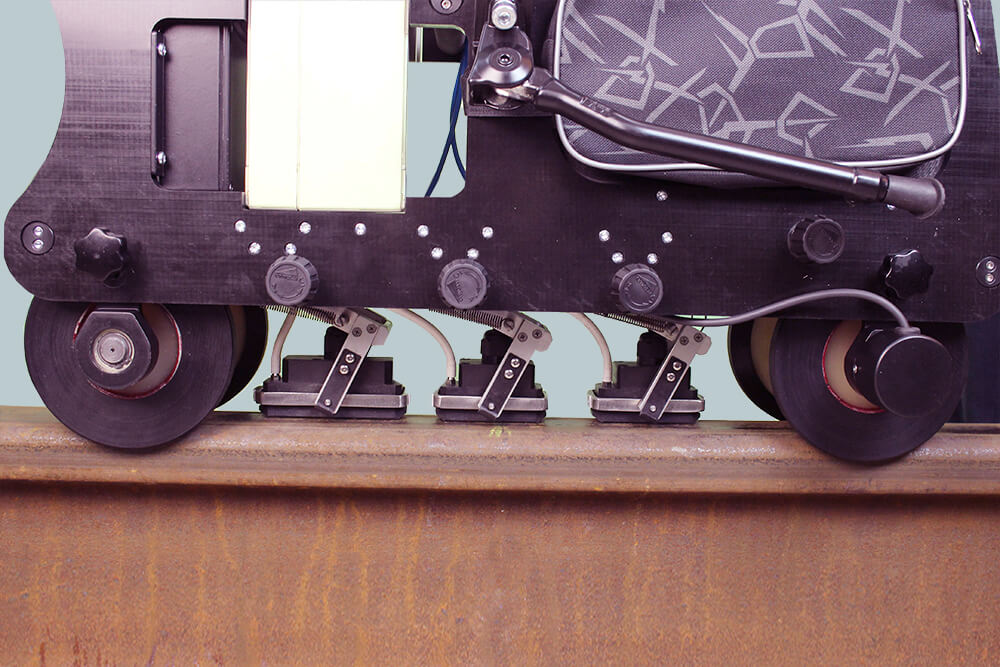

Roller search unit (with immersion probes) of handpush cart for ultrasonic rail inspection.

-

Probe units can be of two types

The UDS2-77 flaw detector employs contact probe units of conventional type with both standard and specialized probes.

The probe units are made from wear resistant plastic material, with hard-metal inserts on the working surface.

The slide probe units comprise the following probes:

| UDS2-77 AREMA (RSU) | UDS2-77 AREMA (SL) |

| Provides testing of rails in accordance with AREMA requirements | Provides testing of rails in accordance with AREMA requirements |

| Immersion probe unit design - wheel (RSUI) | Sliding probe unit design (4 sliding blocks) |

| Number of ultrasonic probes - 11 | Number of ultrasonic probes - 11 |

| 0°-4 MHz | 0°-4 MHz |

| 70°-2 MHz (Head Central Forward) | 70°-2 MHz (Head Central Forward) |

| 70°-2 MHz (Head Central Backward) | 70°-2 MHz (Head Central Backward) |

| 70°-2 MHz (Head Gauge Face Forward) | 70°-2 MHz (Head Gauge Face Forward) |

| 70°-2 MHz (Head Gauge Face Backward) | 70°-2 MHz (Head Gauge Face Backward) |

| 70°-2 MHz (Head Field Face Forward) | 70°-2 MHz (Head Field Face Forward) |

| 70°-2 MHz (Head Field Face Backward) | 70°-2 MHz (Head Field Face Backward) |

| 2x40°- 2 MHz (Web, Foot Forward / Backward) | 2x45°- 2 MHz (Web, Foot Forward / Backward) |

| 2x50°- 2 MHz (Head Side Looking) | 2x50°- 2 MHz (Head Side Looking) |

Key features:

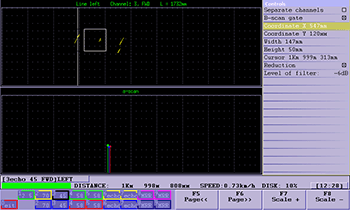

- Representation of test results in the form of A-scan, multi-A-scan, B-scan for all channels;

- Real-time display of test results in the form of B-scan

- Data recording and saving (operator’s name, line, direction, track number, left/right position, initial track coordinate, date, time, final track coordinate);

- Screenshot saving (PrintScreen);

- Saving of test results in the form of data array (B-scan) to the internal memory;

- Use of USB flash drive for transmitting test results to PC;

- Availability of measuring gates in A-scan & B-scan modes;

- Post-viewing of test result on the flaw detector with the possibility to measure conditional sizes of defects;

- Possibility to put the track markers (e.g. “Bridge”, “Crossing”, “Bolt hole”, etc.).

-

Suspension mechanism of Slide Search Unit

The suspension mechanism is responsible for positioning the slide probe unit in the rail head cross-section. It also ensures a steady acoustic coupling when the cart is turned by ±15°.

Fig. 3 — Suspension mechanism. Working position (lever down)

Fig. 4 — Suspension mechanism. Transport position (lever up)

Fig. 5 — Adaptive wheels

-

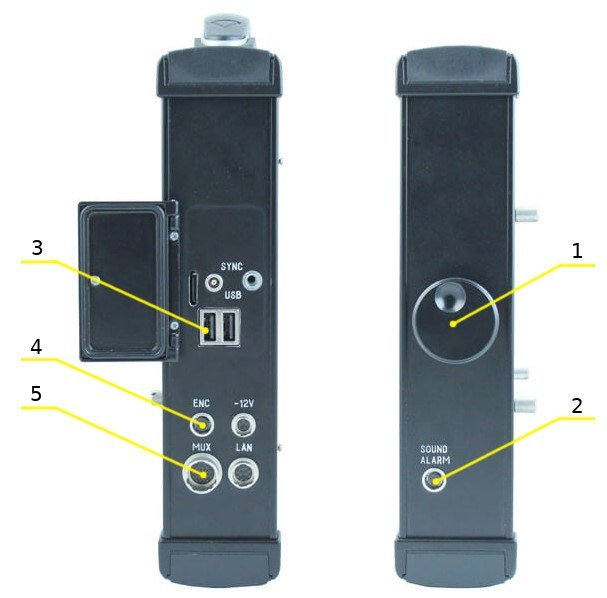

Electronic unit of UDS2-77

1 — Control Knob to change operation modes and parameter values in the software interface;

2 — Connector for headphones;

3 — Connector for USB-drive;

4 — Connector for Encoder;

5 — Connector for Multichannel (MUX).

-

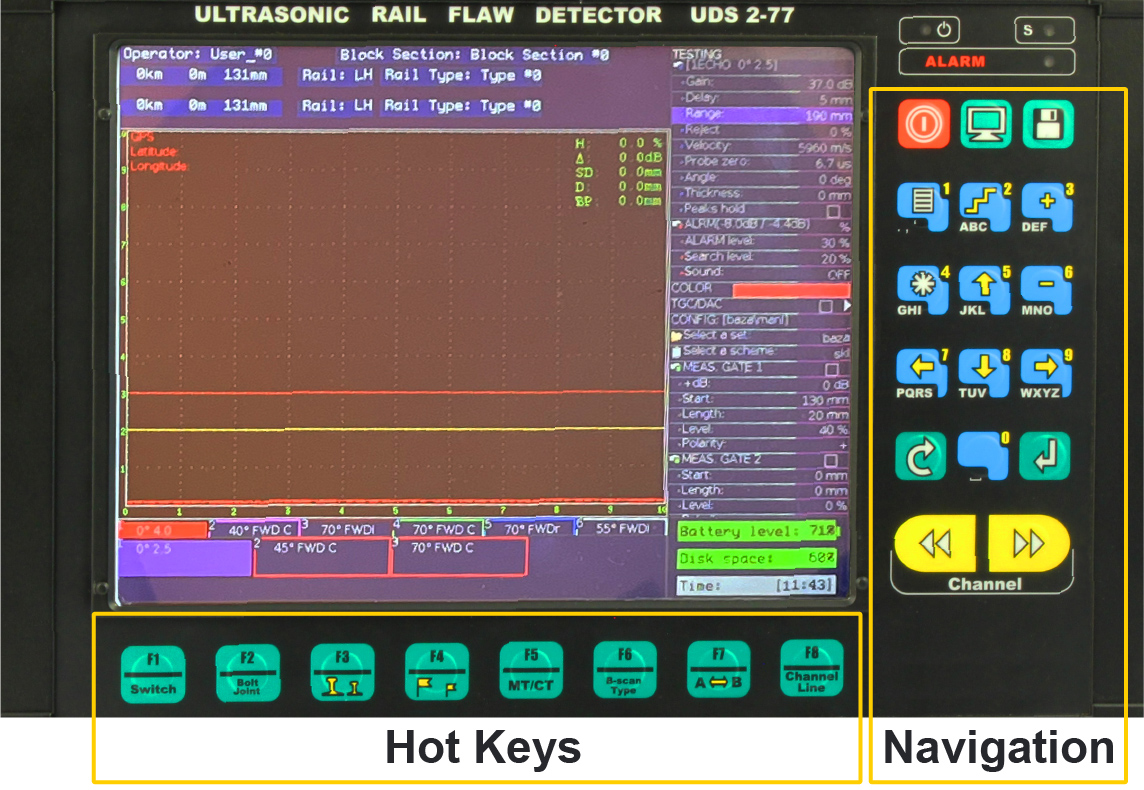

Keypad

Keypad of UDS2-77 flaw detector consists of two navigation panels that are used for browsing through the menu items, modifying the parameter values, and calling for various operation modes with the aid of ‘hot’ keys.

The UDS2-77 features a simple menu structure for setup and calibration, as well as setting of software functions/modes. The device is furnished with the Hot Keys panel to get an immediate access to main operation modes, such as display (А-scan/B-scan), correction of track coordinate, generation of test report, On/Off button for test result saving mode.

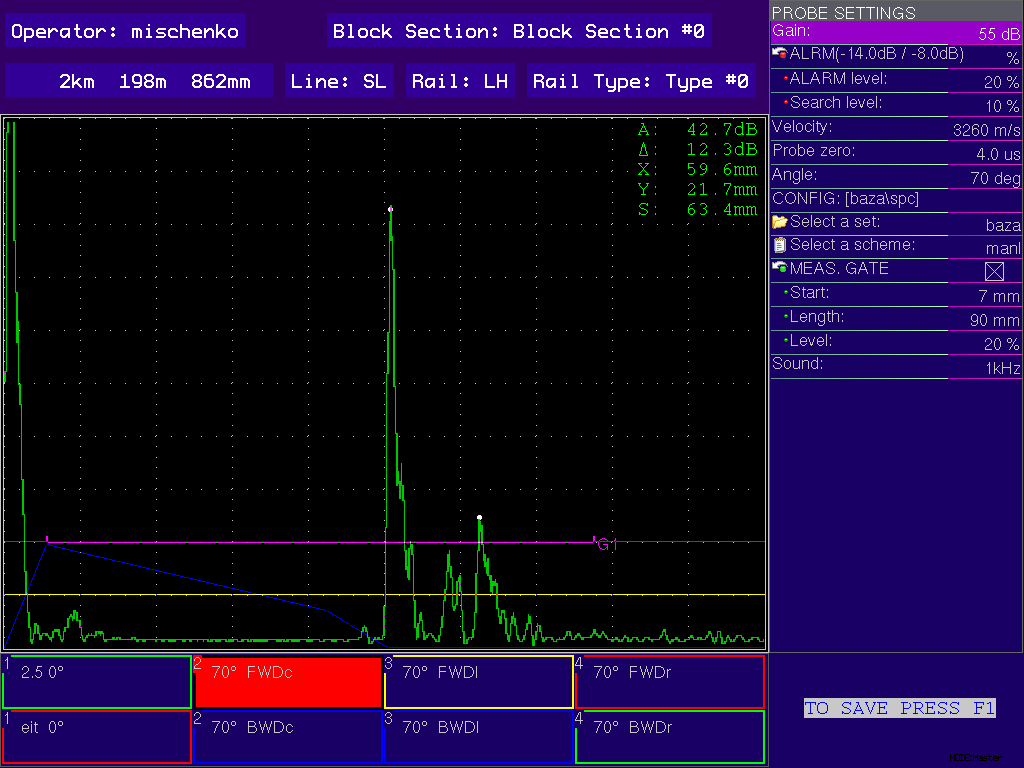

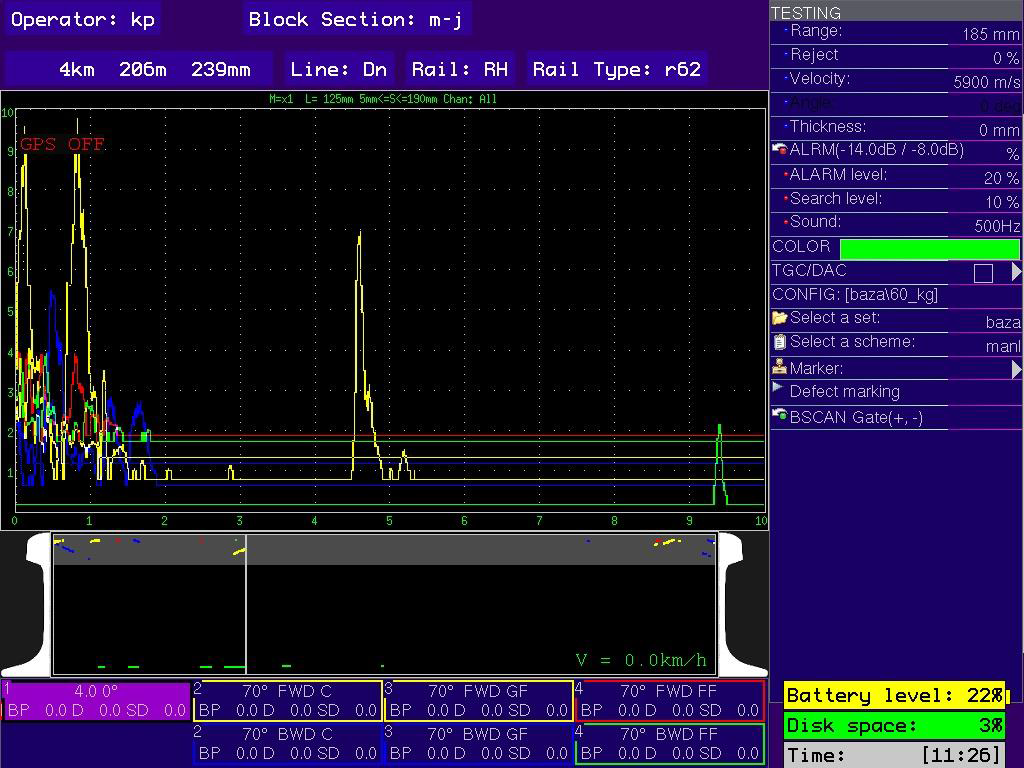

A-scan

B-scan

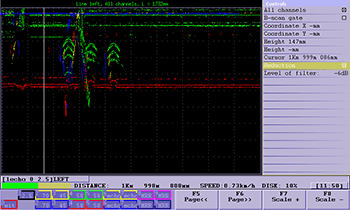

Multi A-scan + B-scan

Fig. 6 — Test result display modes:

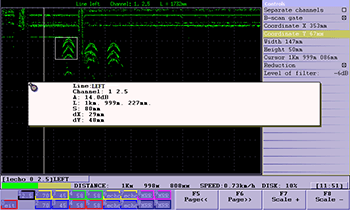

Test result post-viewing mode

a) Viewing the general menu

b) Measuring flaw parameters

c) Viewing B-scan + A-scan

Fig. 7 — Test result viewing mode

UDS2-77 AREMA RSUI

- Probe Unit RSUI:

- one 0-degree transducer, 2 or 4 MHz

- two 45-degree transducer, 2 MHz

- six 70-degree transducers, 2 MHz

- two 55-degree transducer, 2 MHz

UDS2-77 AREMA RSUI RSC (for continuous control of railway switches)

- Probe Unit RSUI:

- one 0-degree transducer, 2 or 4 MHz

- two 45-degree transducer, 2 MHz

- six 70-degree transducers, 2 MHz

- two 55-degree transducer, 2 MHz

UDS2-77 AREMA SL

- Probe Unit 1 (Central Line):

- 0°-4 MHz

- 70°-2 MHz (Forward Central head)

- 70°-2 MHz (Backward Central Head)

- Probe Unit 2 :

- 2x45°- 2 MHz (Forward / Backward Central head)

- 2x50°- 2 MHz (Side looking)

- Probe Unit 3 (Gauge side):

- 70°-2 MHz (Forward Gauge face head)

- 70°-2 MHz (Backward Gauge face head)

- Probe Unit 4 (Field side):

- 70°-2 MHz (Forward Field face head)

- 70°-2 MHz (Backward Field face head)

UDS2-77 EU

testing of a rail in the web projection

- Probe Unit 1 (Central Line):

- 0°-4 MHz

- 70°- 2 MHz

- Probe Unit 2 (Central Line):

- 70°- 2 MHz

- 2x45°- 2 MHz

UDS2-77 TRAM

for tram rails control

- Probe Unit 1 (Central Line):

- 0°-4 MHz

- 70°-2 MHz (Forward Central head)

- 70°-2 MHz (Backward Central Head)

- Probe Unit 2 :

- 2x45°- 2 MHz (Forward / Backward Central head)

- 2x50°- 2 MHz (Side looking)

- Probe Unit 3 (Gauge side):

- 70°-2 MHz (Forward Gauge face head)

- 70°-2 MHz (Backward Gauge face head)

- Probe Unit 4 (Field side):

- 70°-2 MHz (Forward Field face head)

- 70°-2 MHz (Backward Field face head)

UDS2-77 AREMA CR

for crane rails control

- Probe Unit 1 (Central Line):

- 0°-4 MHz

- 70°-2 MHz (Forward Central head)

- 70°-2 MHz (Backward Central Head)

- Probe Unit 2 (Gauge side):

- 70°-2 MHz (Forward Gauge face head)

- 70°-2 MHz (Backward Gauge face head)

- Probe Unit 3 (Field side):

- 70°-2 MHz (Forward Field face head)

- 70°-2 MHz (Backward Field face head)

-

UT techniques: pulse echo, (echo image) and echo shadow.

-

Number of ultrasonic channels for 100% scanning: 13.

-

Nominal test frequency: 1 to 6 MHz.

-

Distance between probe pulse sendings: 1 mm at motion speed up to 5 km/h.

-

Variation range of receiving path gain: 0 to 100 dB, with a step of 1 dB.

-

Memory capacity for data storage: not less than 8 Gb.

-

Weight of the flaw detector without battery and couplant: up to 16 kg.

-

The flaw detector is powered by an independent power source (battery) with the rated voltage from 10.8 to 14.6 V and rated capacity of no less than 18 А·h.

-

Time of operating mode setup: up to 15 sec.

-

Time of continuous operation of the flaw detector with a fully-charged battery: no less than 8 hours.

-

Protection rating: IP 64.

-

The following alarms are generated during flaw detection: light – separate for every rail and common (via all test channels); sound – separate for every rail and common (for a group of channels); visual, on the screen – separate for every rail and every channel.

-

GPS system is used to determine defect location coordinates on the track.

| № | Description | Q,ty, pcs. | Notes |

|---|---|---|---|

|

1 |

Trolley |

1 pc. |

Composition according to specification |

|

2 |

System of couplant supply to probe units |

1 set |

Included as a part of trolley |

|

2.1 |

- tank |

1 pc. |

|

|

2.2 |

- tubes |

1 set |

|

|

2.3 |

- distributors |

1 set |

|

|

3 |

Electronic unit |

1 pc. |

Included as a part of trolley |

|

4 |

Multichannel unit (MUX) |

1 pcs. |

Included as a part of trolley |

|

5 |

Power switching unit |

1 pc. |

Included as a part of trolley |

|

6 |

Probe unit |

2 pcs. |

Included as a part of trolley |

|

7 |

Battery pack |

2 pcs. |

1 pc. included as a part of trolley |

|

8 |

Charger |

1 pc. |

|

|

9 |

Manual probe TSD4-20 |

1 pc. |

Manual testing |

|

10 |

Manual probe TAB2-45-14x14 |

1 pc. |

Manual testing |

|

11 |

Manual probe TAB2-70-14x14 |

1 pc. |

Manual testing |

|

13 |

Connecting cable from multichannel unit (MUX) to probe |

1 pc. |

|

|

14 |

Connecting cable from multichannel unit (MUX) to probe |

1 pc. |

|

|

15 |

Calibration block |

1 pc. |

Type of calibration block according to applicable regulatory documents or Customer’s requirements |

|

16 |

Tools and accessories |

1 set |

|

|

17 |

Spare parts |

1 set |

|

|

18 |

USB flash drive |

1 pc. |

|

|

19 |

Application-dependent software |

1 set |

|

|

20 |

Carrying case for transportation and storage |

1 pc. |

|

|

21 |

Operational documentation |

1 set |

|

|

22 |

Case bag |

1 pc. |

|